RECYCLING BIN PROJECT FOR UFF

(2025)

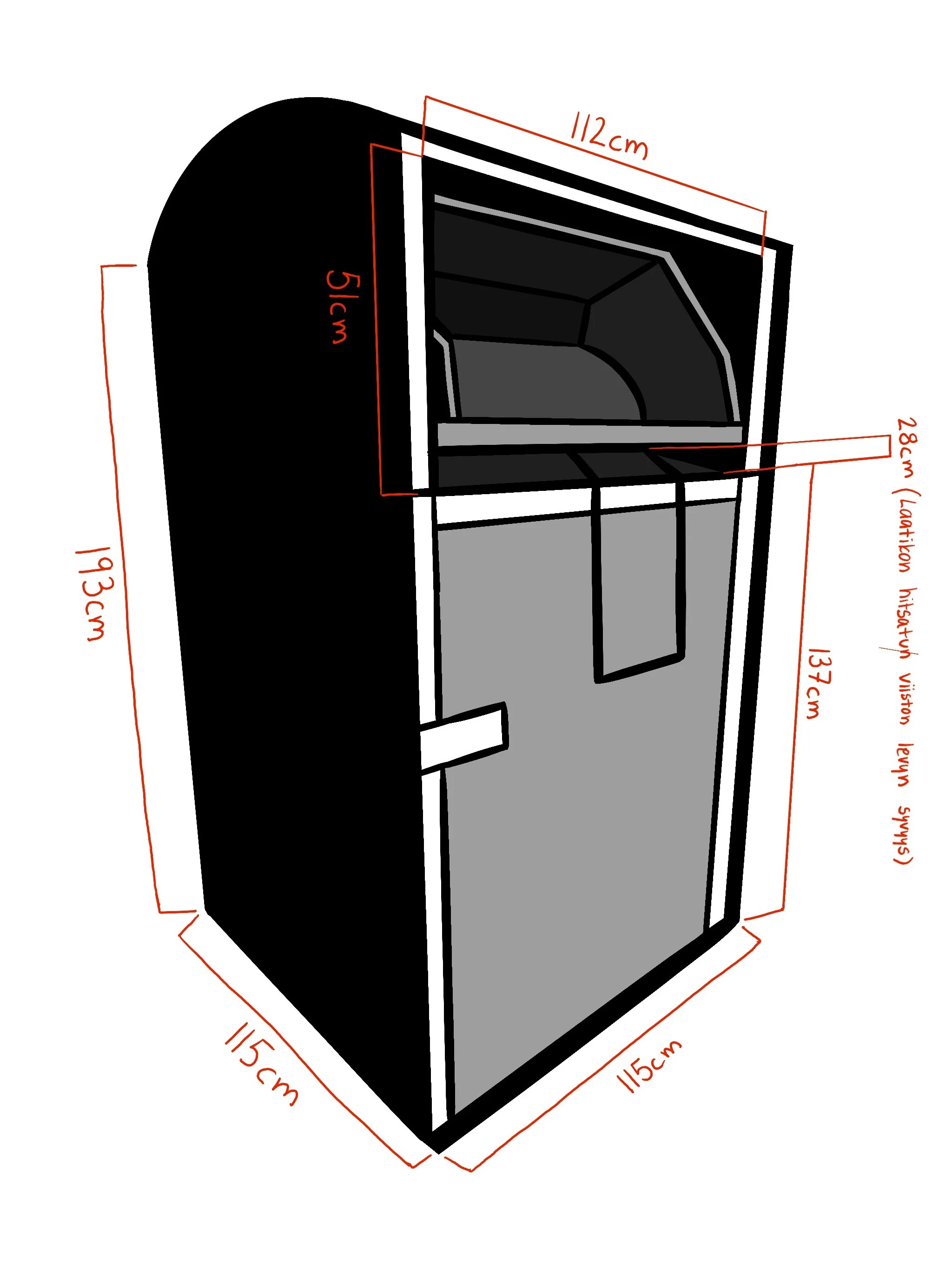

The project was carried out in collaboration with UFF and was a school assignment. In addition to myself, the project team consisted of three other students. In short, the client was UFF, and the task was to innovate and develop a solution to reduce the damage and contamination of recyclable textiles intended for sale inside recycling collection bins. A limiting factor was that the external appearance of the bins could not be significantly altered; instead, the existing recycling bins had to be utilized, and a new function needed to be innovated to keep the textiles clean.

All sketches, photographs, and models related to the project were created or taken by me.

Project overview

We began the project by dividing responsibilities. I took responsibility for the design, modeling, and drawing work. During the group work, we did not appoint a project manager; however, throughout the course I made sure schedules were followed, attendance was maintained, and that everyone participated in the project.

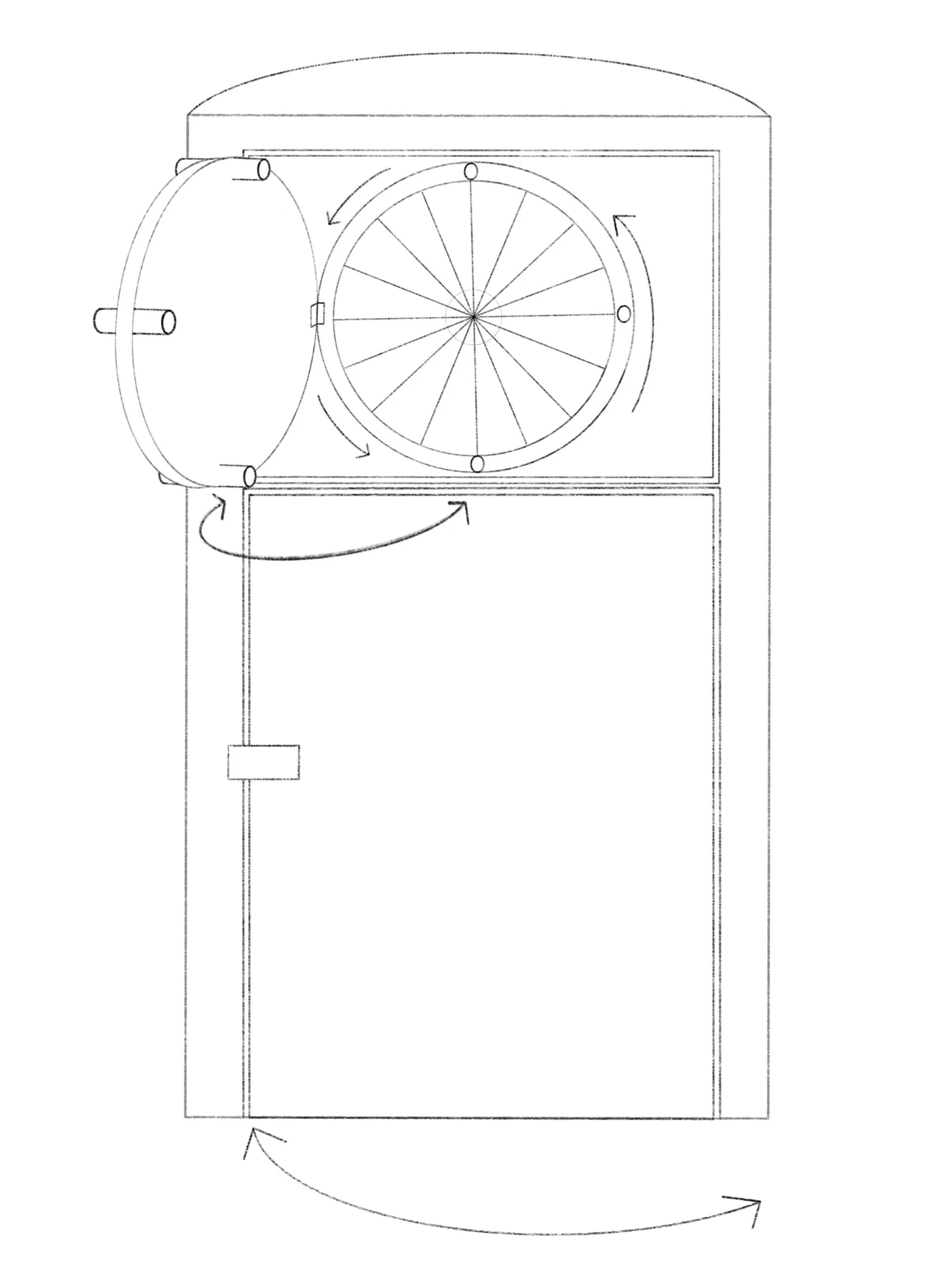

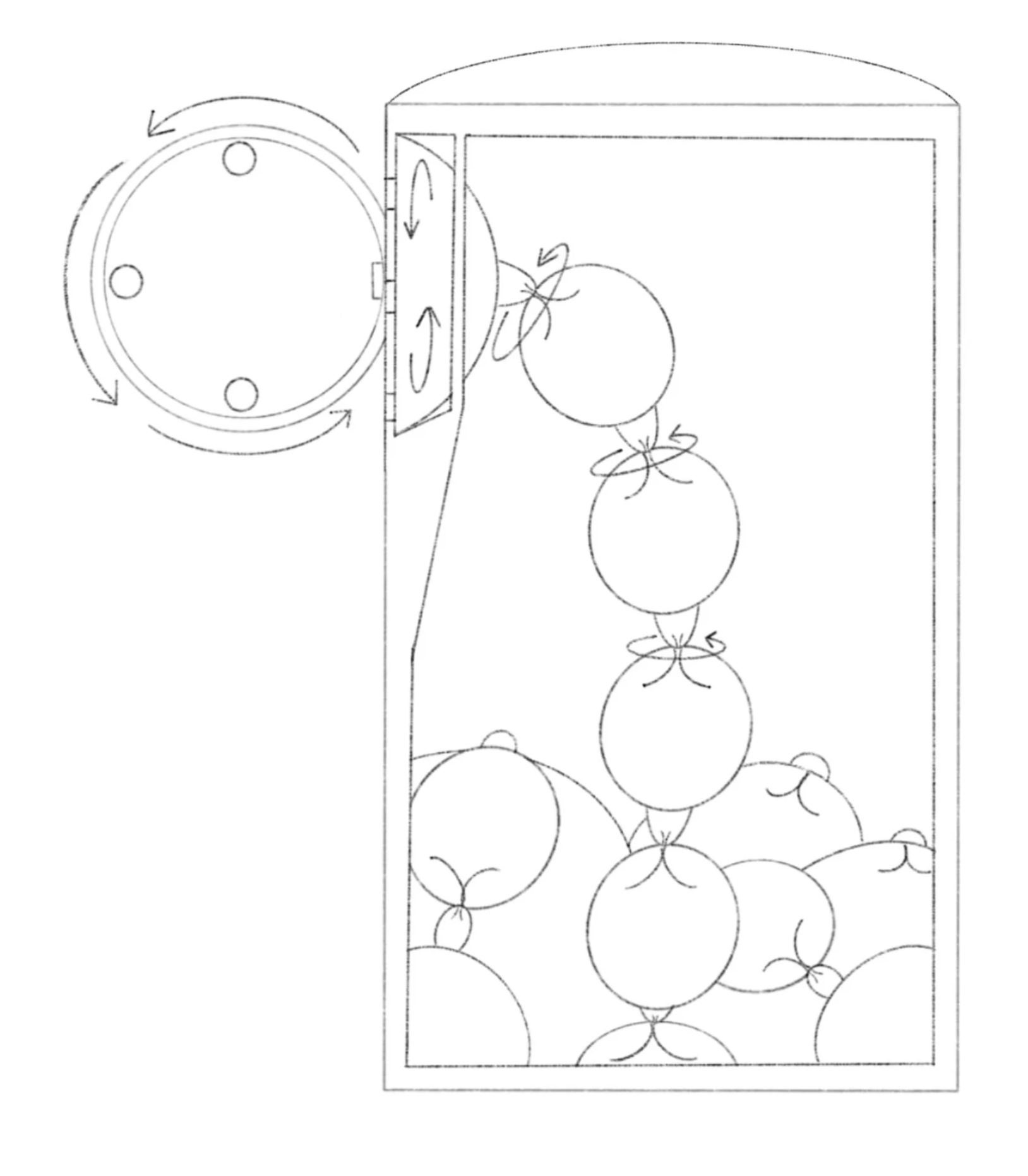

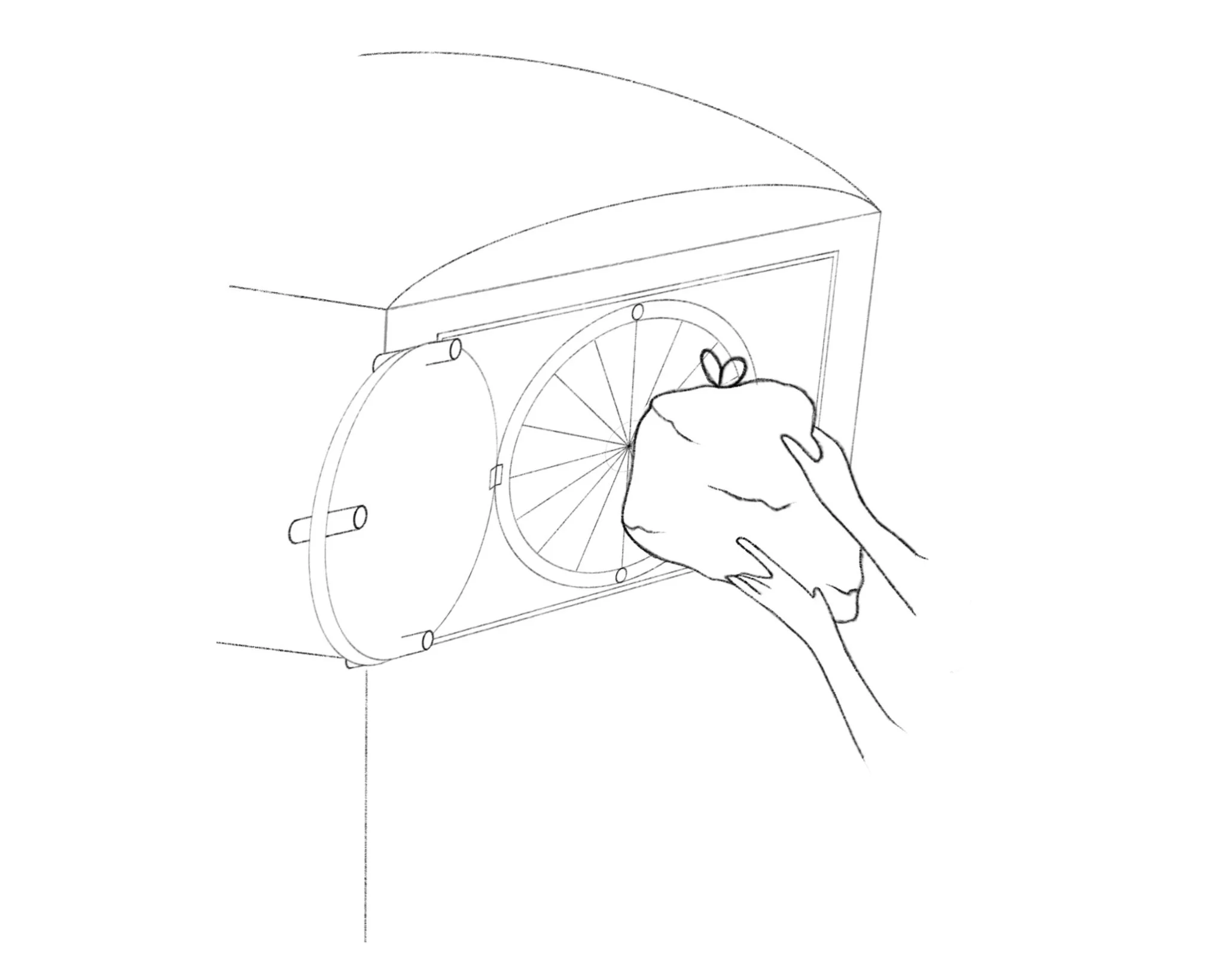

We came up with many ideas, but ultimately we were inspired by a type of diaper disposal bin and its mechanism. The diaper bin mechanism consisted of a rotating cassette in the lid that twists the plastic bag closed, almost like tying a knot. By utilizing this mechanism, we were able to address a major problem faced by UFF.

Each donation would therefore be kept separate inside the bin, allowing the textiles to remain dry and clean. The mechanism also did not require electricity, which was an important function and feature we were looking for. The bin needed to function in any location and in any weather conditions. The mechanism could be installed in place of the existing recycling hatches, meaning that current collection bins could continue to be used.

First, I went and took pictures of the existing bins so we could get the measurements, and I could start sketching.

Starting point

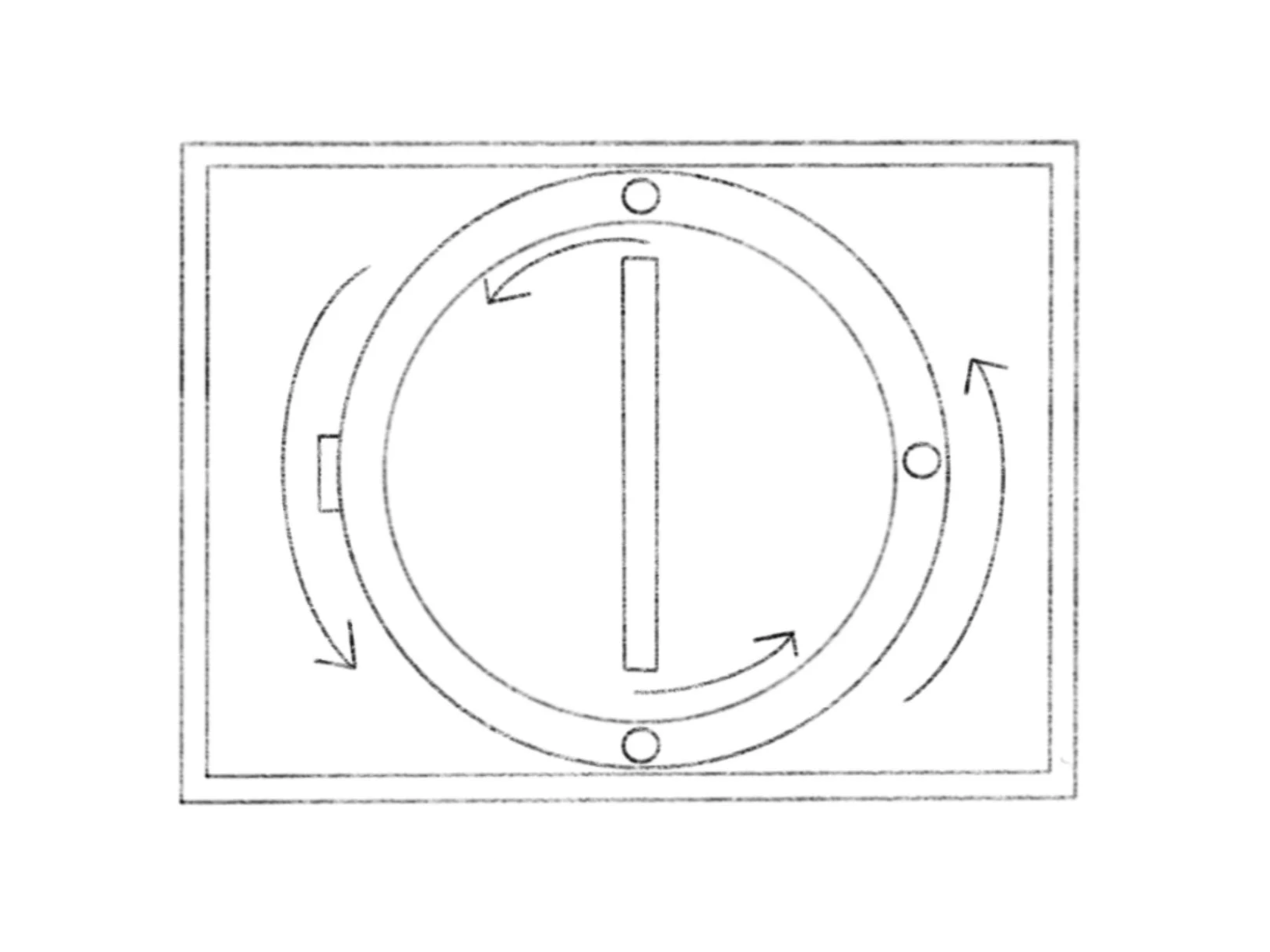

SKETCHING PHASE

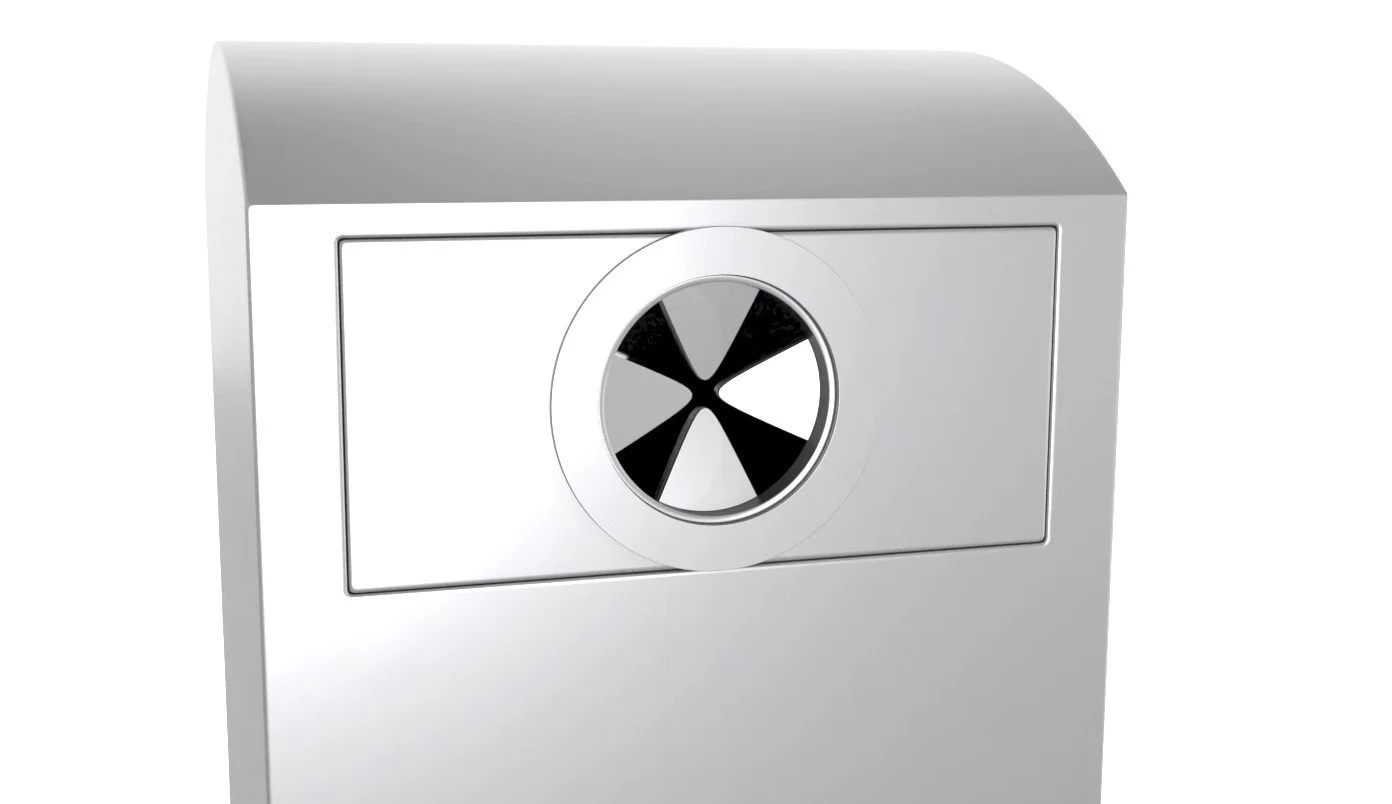

Based on our ideas and my sketches, I created the first quick model of a UFF recycling collection bin in Rhino software, so we could better understand what we were designing and creating.

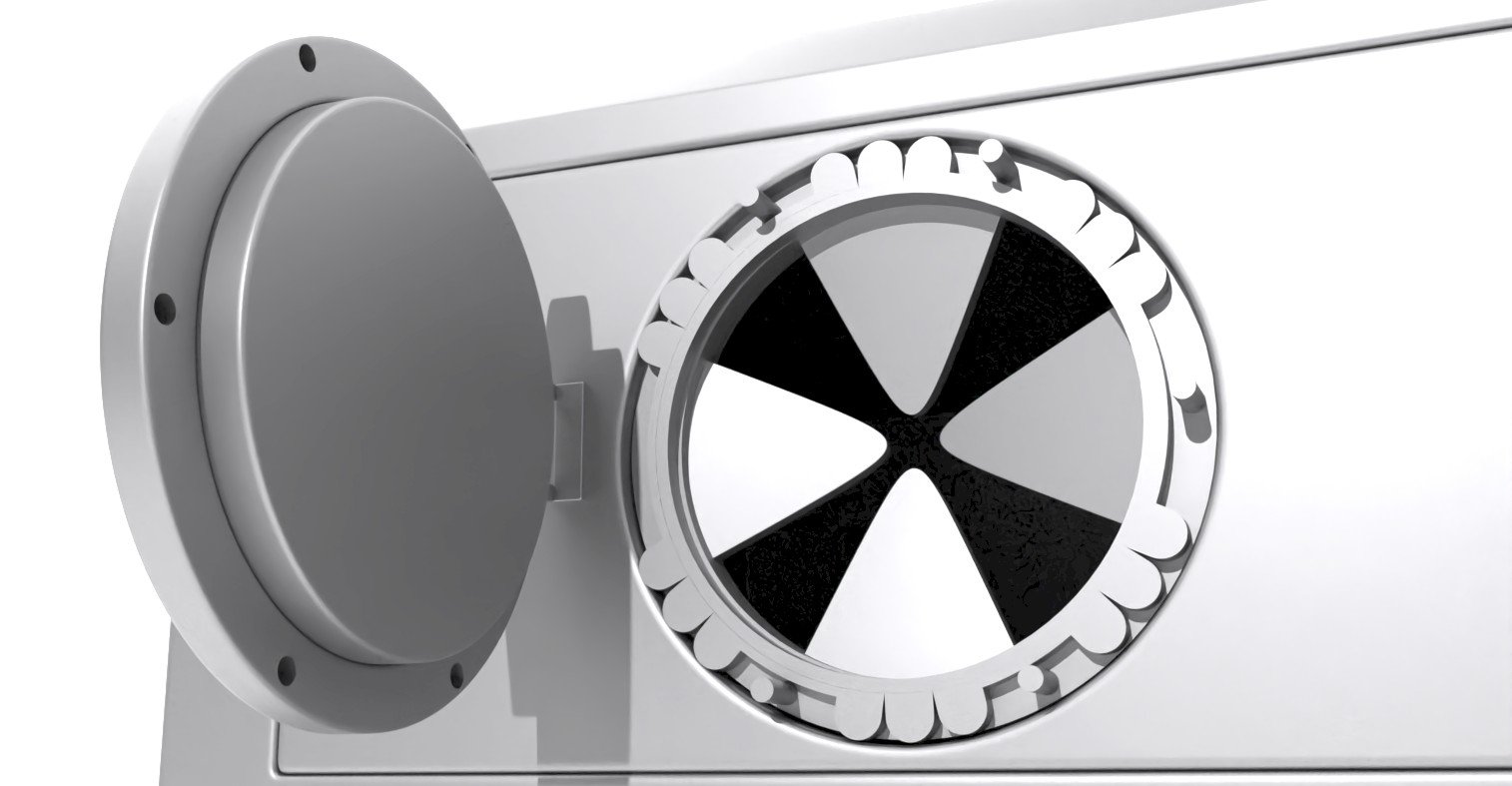

Clothing (with or without a bag) is inserted through the hatch, which is then closed. When the hatch is rotated, the plastic attached to the rotating cassette twists tightly around itself, ensuring that the clothes are protected and remain clean while waiting to be collected.

3D modeling (first drafts)

3D models (final product)

“Through the project, I learned time and project management skills as well as how to work in multidisciplinary collaboration. My 3d modeling and sketching skills improved significantly, and I also gained a great deal of confidence in my work and in my presentation skills.”