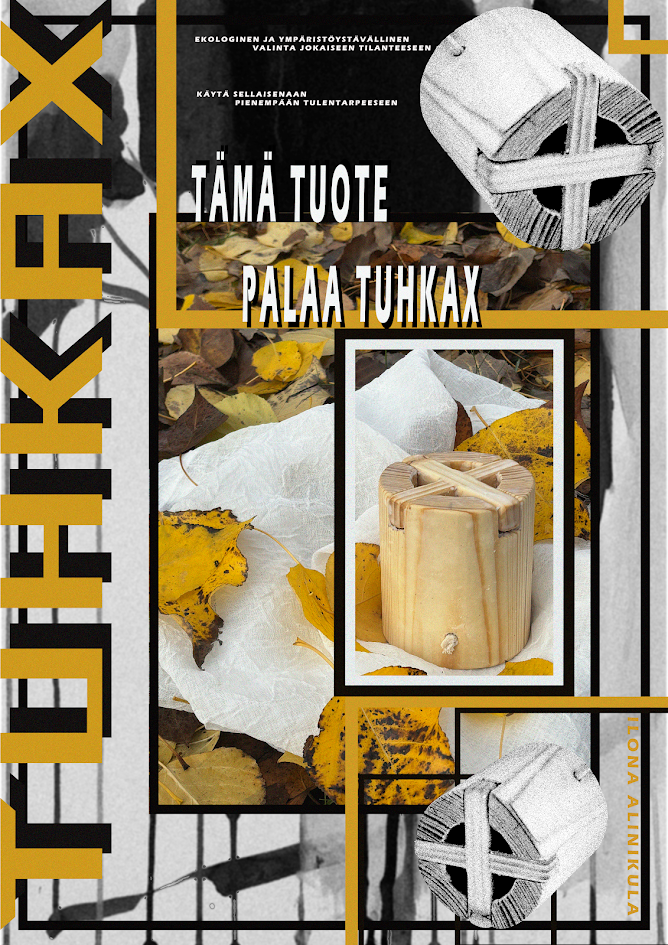

BIODEGRADABLE CAMPFIRE SOLUTION

(2025)

The project was to create a fully biodegradable fire-starting kit to create a campfire. In this case, a fire-starting kit means that it contains everything needed to start a fire, and no skill or additional products are required to assemble the fire, other than matches. The fire-starting kit can be used as a quick campfire on its own or as a base to ignite a larger fire.

All sketches, products, videos, photographs, and models related to the project were created or taken by me.

Project overview

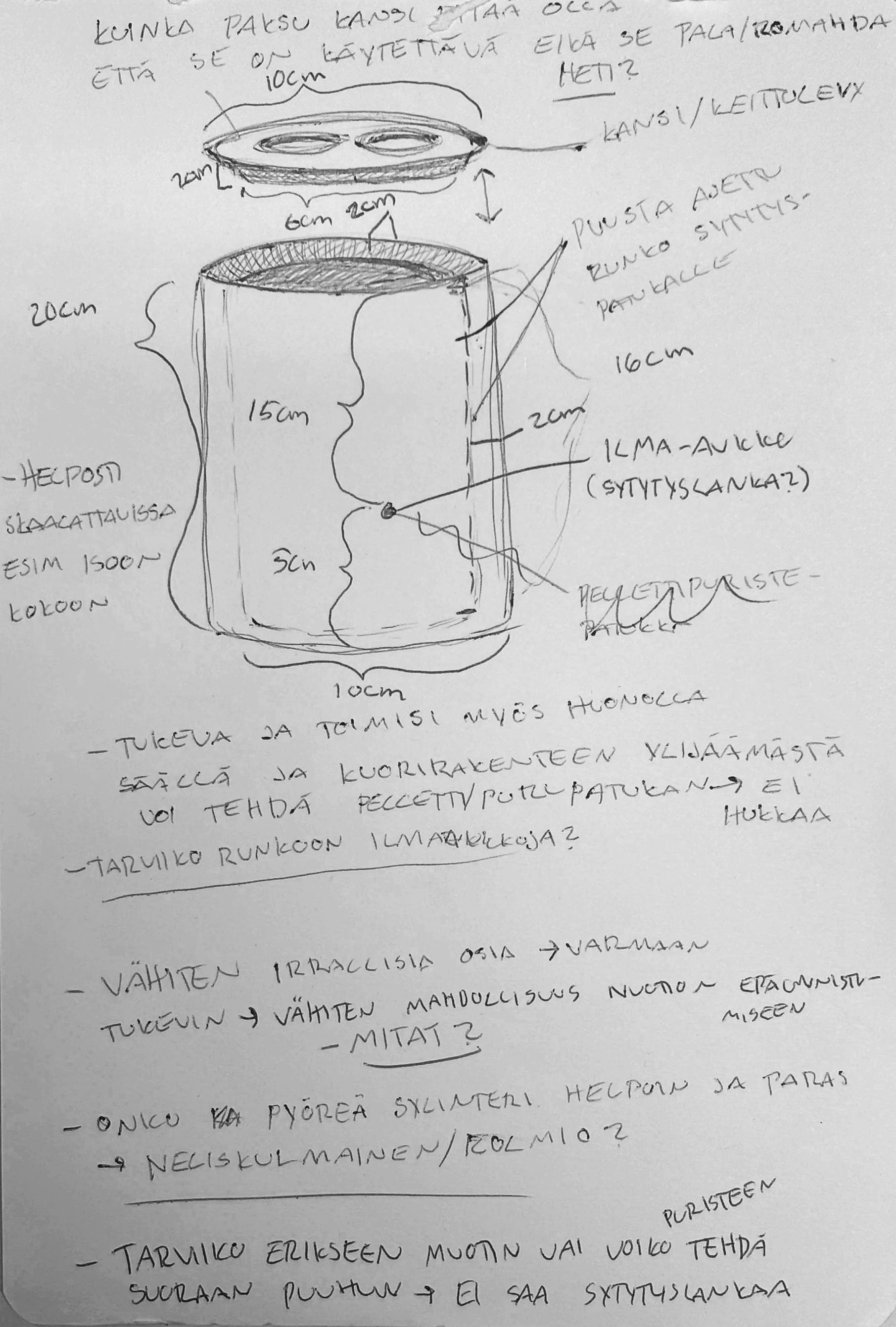

I started by jotting down ideas and defining the target user group. I wanted to design a product for people who have no previous experience with starting a fire and are looking for an easy, compact product that fits in a backpack and helps them start a fire easily. It was important to me that the product also offered a solution for quickly heating something on it. I sketched a lot on paper and thought about different solutions for this project. All of my sketches had a cylindrical shape, so I went with it.

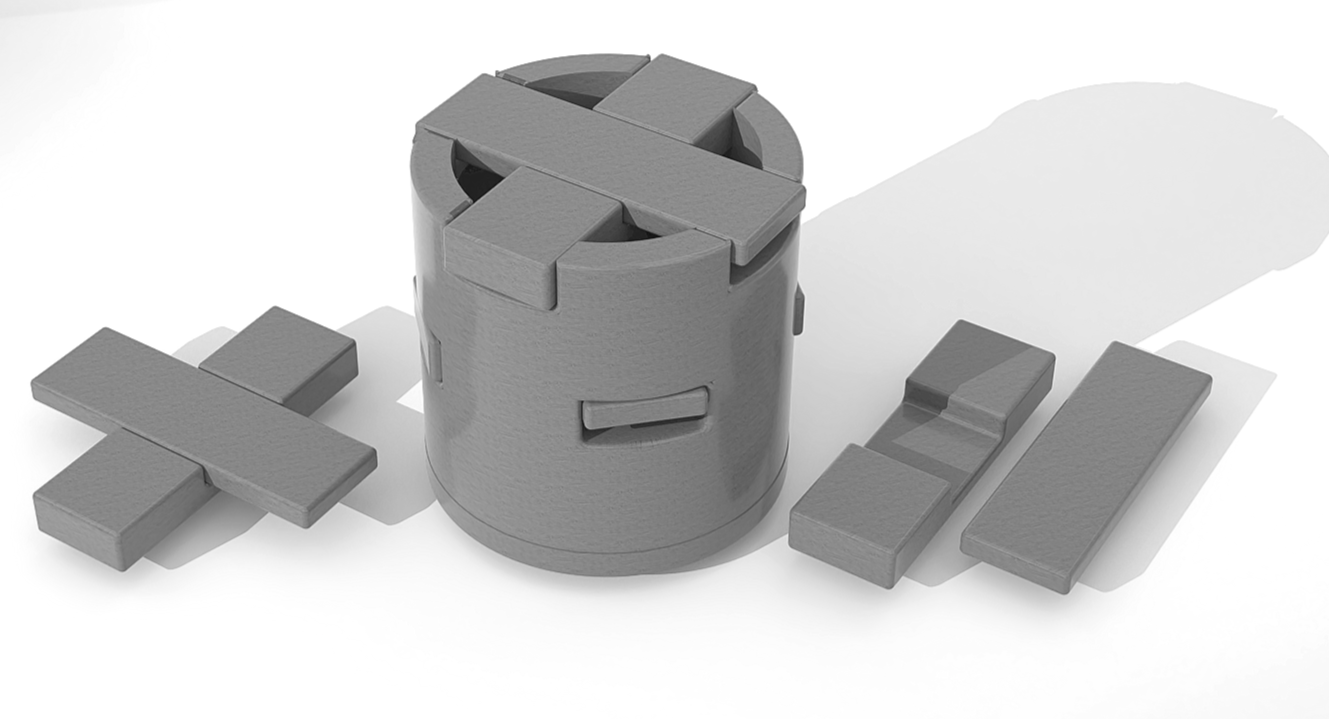

Next, I made quick prototype experiments using leftover wooden blocks and cardboard, and modeled different versions in Rhino based on my sketches and experiments. There was also a cross-like structure inside the shell, but after doing tests with the product, I did not feel like it was necessary, so I left it out.

Starting point

I started by creating a test piece from wood based on my final idea, which would later become the finished product. It was good to first make an experimental version and see how it worked as a whole, make any final adjustments, and then create a more polished final product. I hollowed out the wooden log using a router and cut openings for the crosspieces with a bandsaw. I was able to assemble the cross-frame structure using leftover pieces from the frame. The challenging part was getting the openings for the crosspieces to be accurate and straight on the round shape. I sanded the product, aiming for a refined and clean appearance. I drilled a hole for the ignition cord, which would help ensure the product burned evenly and make the ignition process easier. The product was starting to look neat and like the final version. I sanded the product, aiming for a refined and clean appearance. I drilled a hole for the ignition cord, which would help ensure the product burned evenly and make the ignition process easier. The product was starting to look neat and like the final version.

PROTOTYPING PHASE

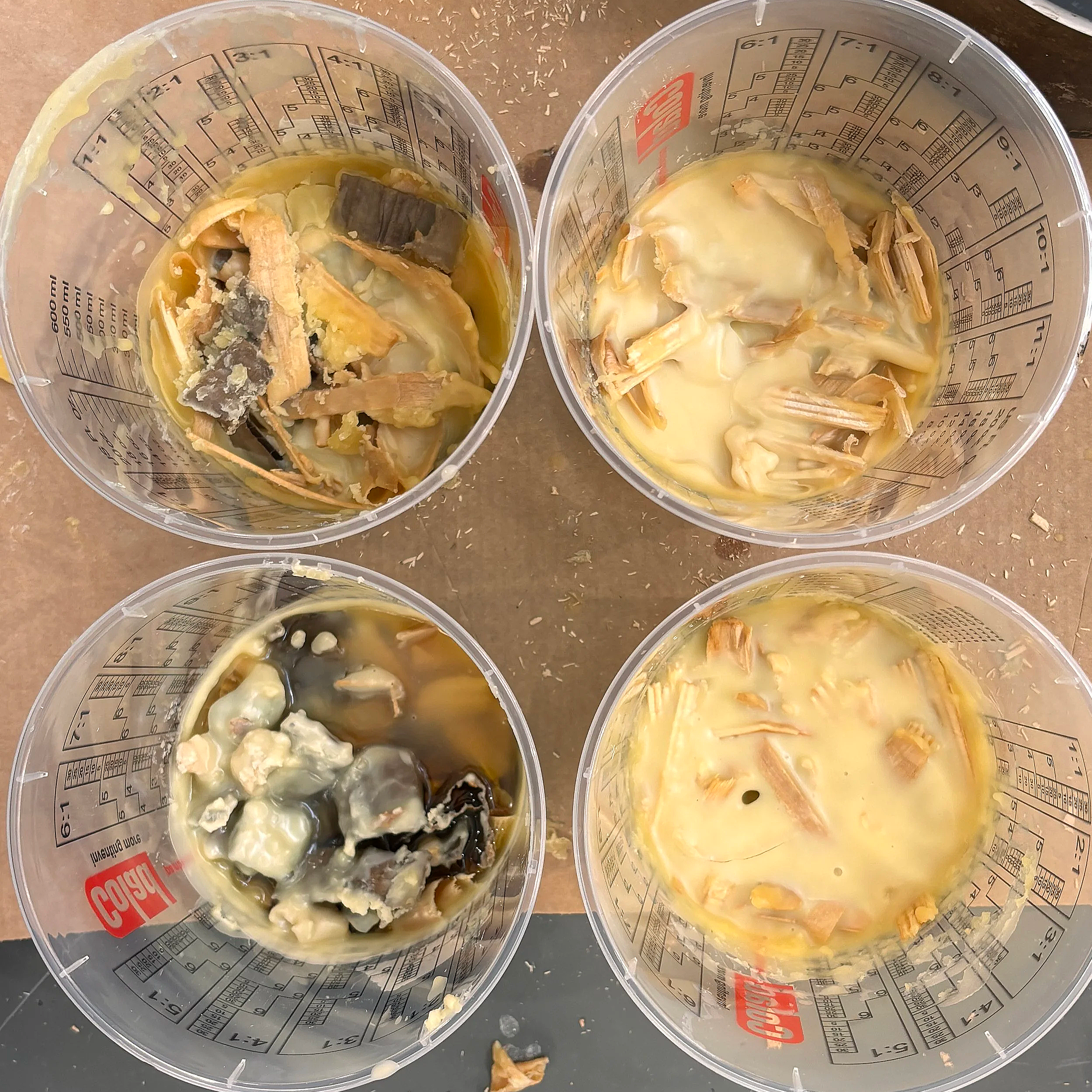

I conducted various tests to see how different wood shavings, cardboard, and beeswax burned (for the final product, I wanted to choose soy wax because of its environmental friendliness and plant-based origin). The best combination for burning was a mix of wax, cardboard, and thin wood strips. This was an interesting and important experiment for the functionality of the product, and it was surprising how the different mixtures burned at different rates and in different ways.

I wanted the ignition cord to be placed inside the shell so that the product would burn as evenly as possible and it would be clear to an inexperienced user how the product works, without the need for separate instructions. I dipped the ignition cord in wax and let its end protrude outside the hole made in the shell. At this stage, I also layered wood shavings, cardboard, and wax inside the shell.

I coated the assembled product thoroughly with soy wax, as the product is primarily made of wood, and keeping it dry is essential for starting a fire. The soy wax created a sort of "film" on the product’s surface, helping it withstand moisture in extreme conditions and making it water-resistant. The product is not waterproof, but thanks to the coating, it can endure rain and sleet at the time of ignition. I considered this an important feature for a Finnish outdoor product. I put my fire-starting kit to the test during a snowstorm in the dead of winter. It lit up beautifully, and the top cross-section held up for a good amount of time. It was incredibly satisfying to watch my product come to life and perform so well.